Solutions

-

approximately

20~40m/sSpeeding up of finishing speeds

Production Volume Increase

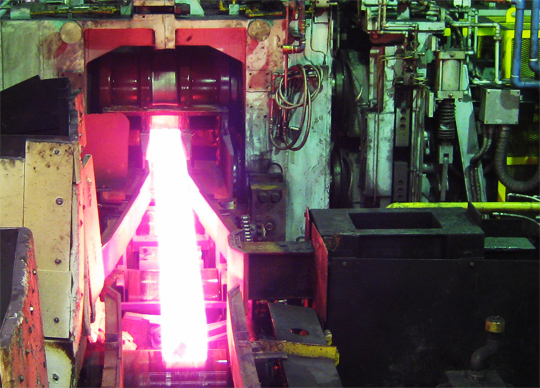

High speed rolling technology

Increased production volume and stable operations become possible through high speed rolling technology.

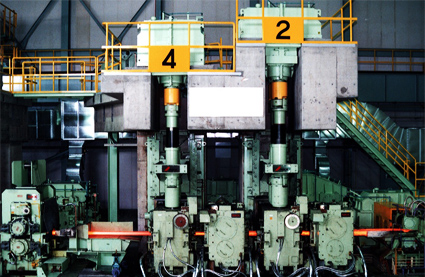

Block mills

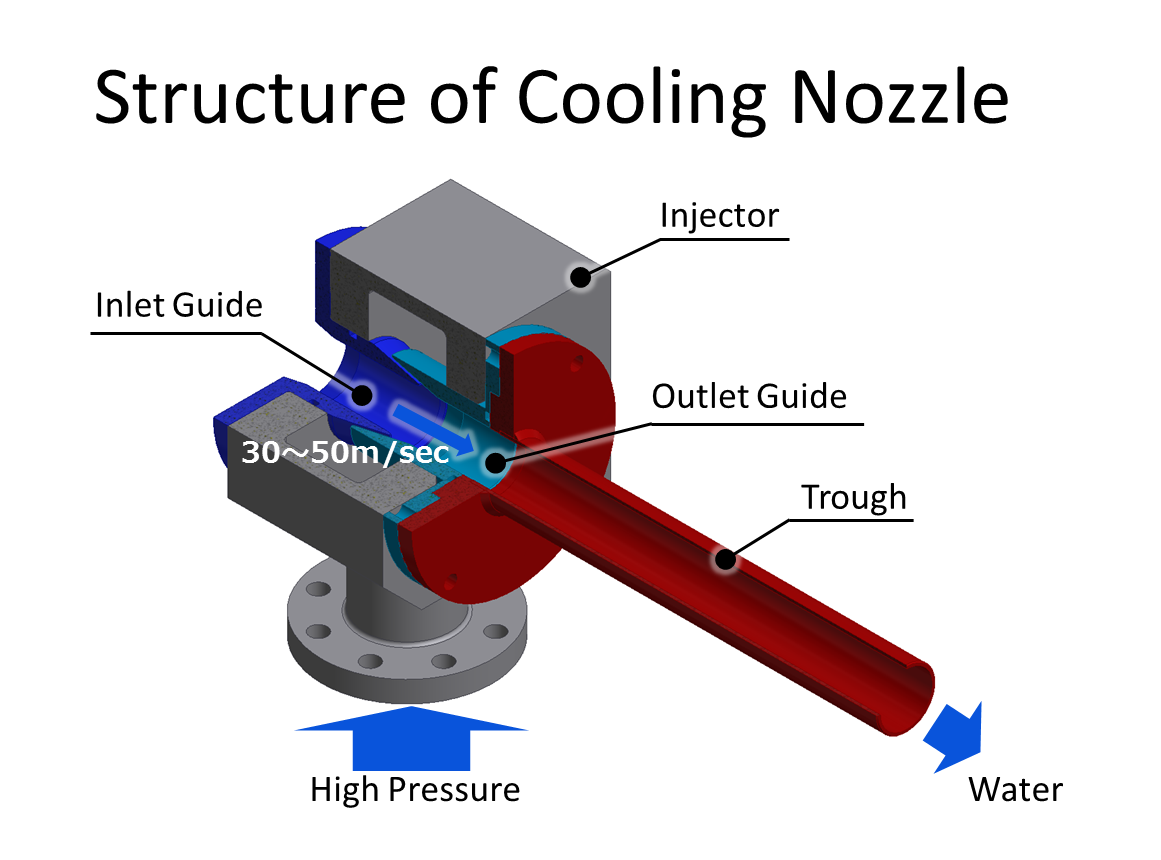

Using a block mill, which drives multiple rolling mills and has been used on 100m/s class wire rod lines, as the bar steel finishing mill, will achieve speeds far beyond the finishing speed of about 20m/s that was the limit of conventional mills. Rolling using ultra-hard rolls provides advantages such as precise measurements and enhanced surface finish.Additional advantages are easier roll exchange and maintenance.

High Speed Dividing Shears (HSDS)

Ordinarily, shears were start-stop types, which began moving when the shearing point arrived. However, there was a limit to the speed of the blade rotation (shearing speed) because the blades went from a standstill then began rotation and acceleration. Continuous rotating shears were adopted for the HSDS system, enabling faster shearing speeds. This makes stable shearing possible at even faster rolling speeds.

Production Volume Increase

-

75 % increase

in production volume

-

2 % improvement

of yield ratios

-

15 % increase

in operation rate

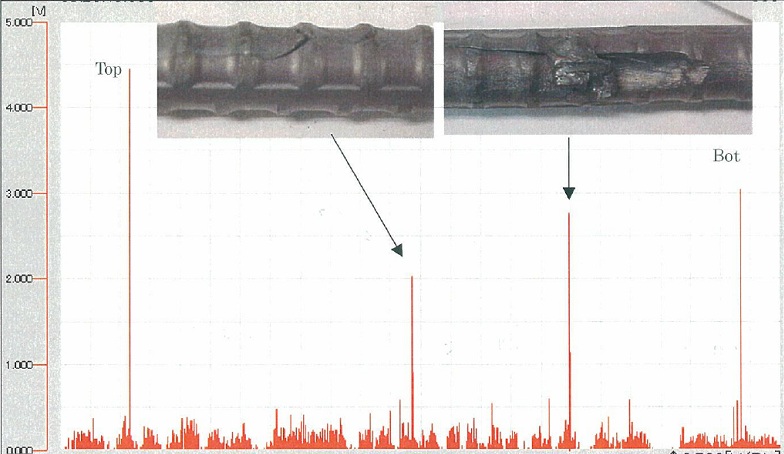

EBROS™ stands for Endless Bar Rolling System. Its objective is to enhance productivity and yield ratios.

Simply put, the function of the EBROS™ is to weld the heads and tails of the billets that are extracted at constant intervals from a reheating furnace, and to create a billet of unlimited lengths.

- It enhances productivity by doing away with gap time

- It does away with cropped items or items of irregular lengths

- It reduces miss-rolls and enables uniform quality

-

0 0Reheating Furnace Fuel Costs

Production Cost Reduction

HDR (Hot Direct Rolling) is a system where the billet from a continuous casting facility is conveyed through roller table and directly input into a mill without being reheated. It is an excellent energy-saving technology.

For the realization of this HDR system, comprehensive engineering capabilities for furnaces and continuous casting and rolling facilities are required. Such includes (1) high-temperature casting technology; (2) technology to minimize the temperature decrease; and (3) optimal layout for delivery to the next process.

We, Steel Plantech, will make the utmost use of these comprehensive engineering technologies to meet our customers’ needs.