Solutions

-

High-Quality Slabs

Product Quality Improvement

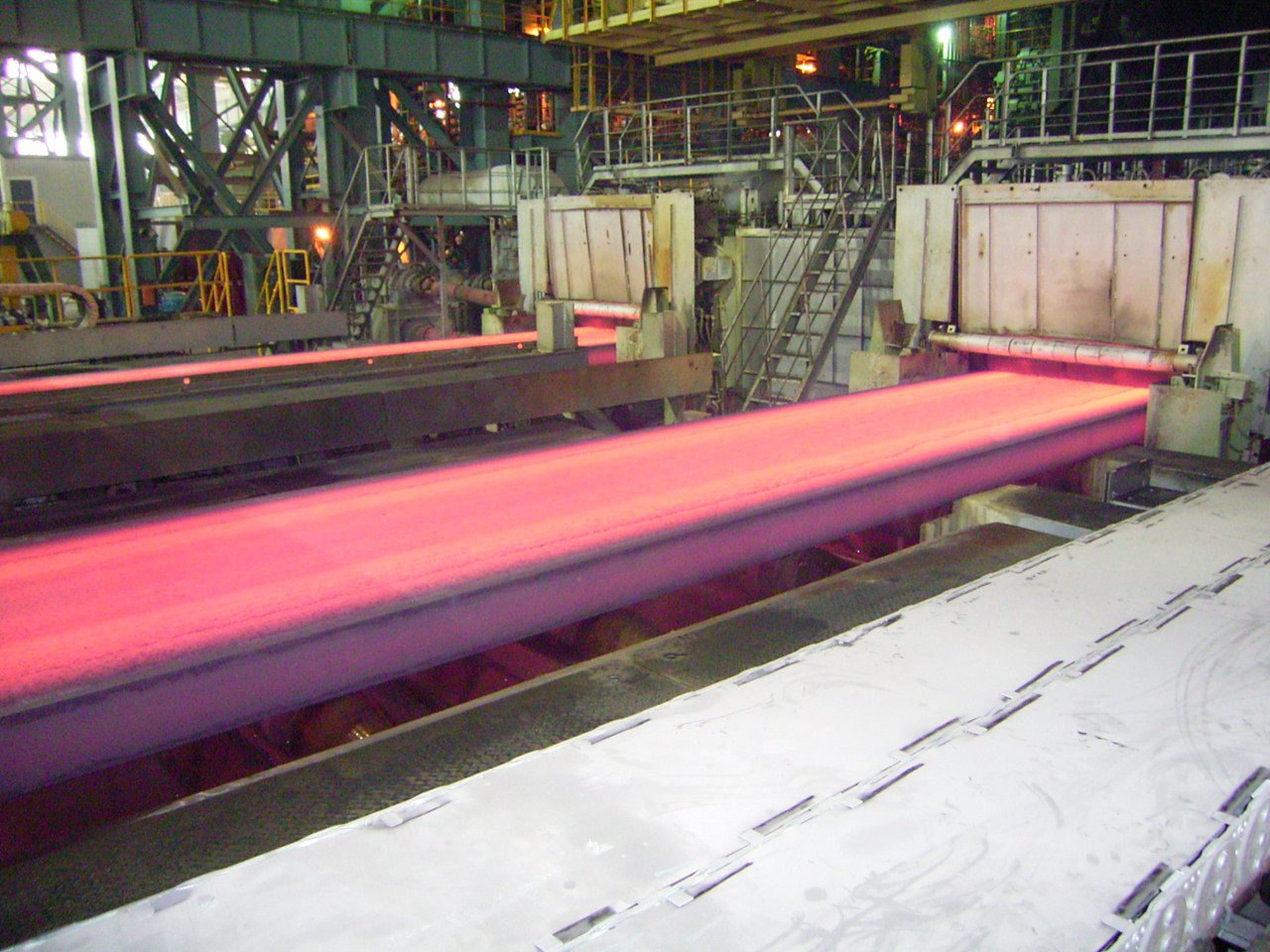

Steel Plantech’s continuous slab caster enhances product quality dramatically through various functions.

- 1Originally developed mold level control system, which suppresses molten steel level fluctuation

- 2Electro-hydraulic oscillator, which makes non-sinuous vibration that reduces friction within the mold possible

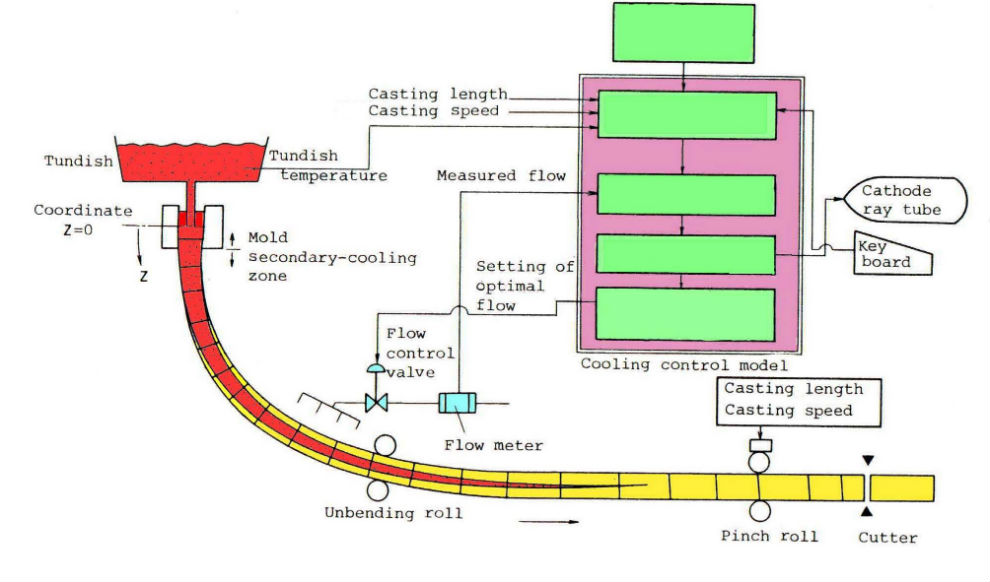

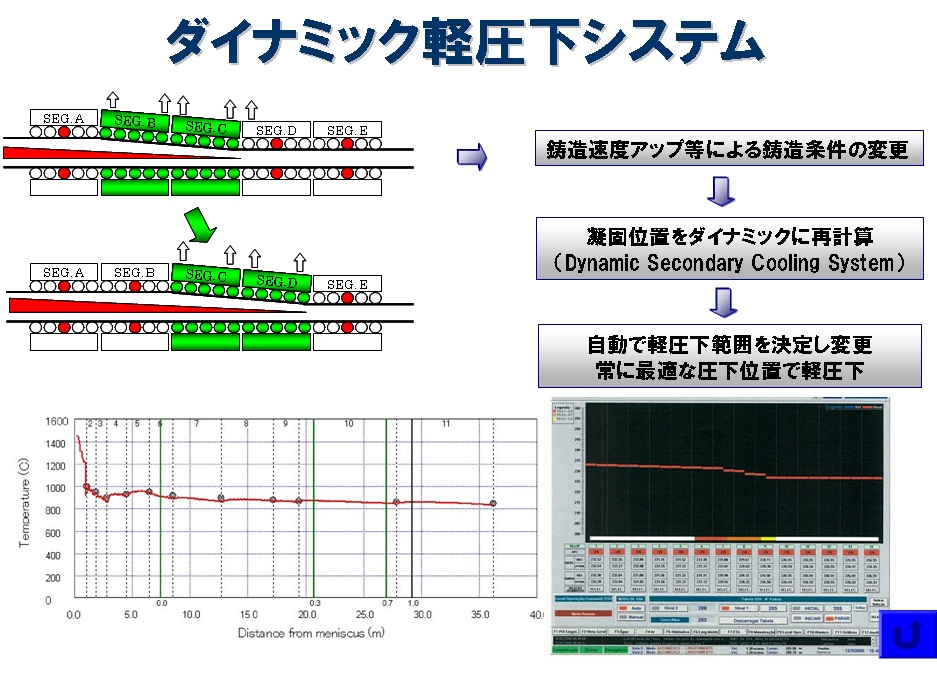

- 3Dynamic secondary cooling system, which realized the optimum thermal profile

- 4Dynamic soft reduction system, which suppresses center segregation, and

- 5Decrease of internal and surface strain of slab through an optimum design of roll profiles.

-

3.0 m/min

high-speed casting

Production Cost Reduction / Production Volume Increase

Cost reductions can be realized through adoption of a Steel Plantech continuous slab caster.

- 1High-speed, stable casting at speeds of over 3.0m/minute allows production of 200,000 tons or more per month per strand, significantly reducing the number of strands

- 2A break-out prediction device (learning type) prevents break outs

- 3The dynamic secondary cooling system and stepless spray-width control system minimizes unsteady portions

- 4A shape increase in operating rate by high durability and advanced maintainability of each equipment

Customization

-

10 Cases

Vertical bending machine remodeling

-

600 mm

Extra-thick casting capable

Responding to customer’s requirements, we contribute to a superior positioning of customers’ products, e.g.;

- 1Revamping work to vertical bending caster in shorter shut down period based on a detailed and careful plan.

- 2Optimum and minimum period renovation planning and on schedule start-up of the machine according to plant facilities’ conditions.

- 3Heavy plate vertical continuous caster that expands the range of heavy plate production by casting.

- 4Dual-use twin/triple-caster machines that make it possible to cast slabs in various sizes.