Solutions

Production Cost Reduction

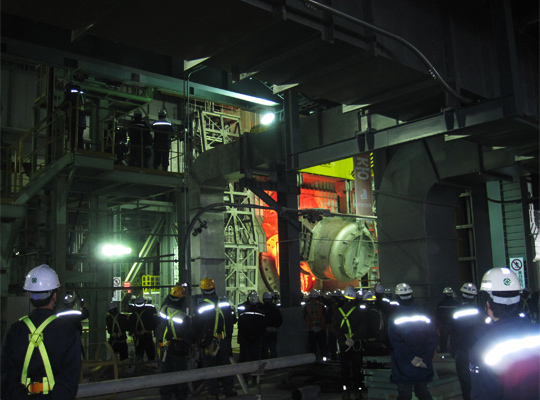

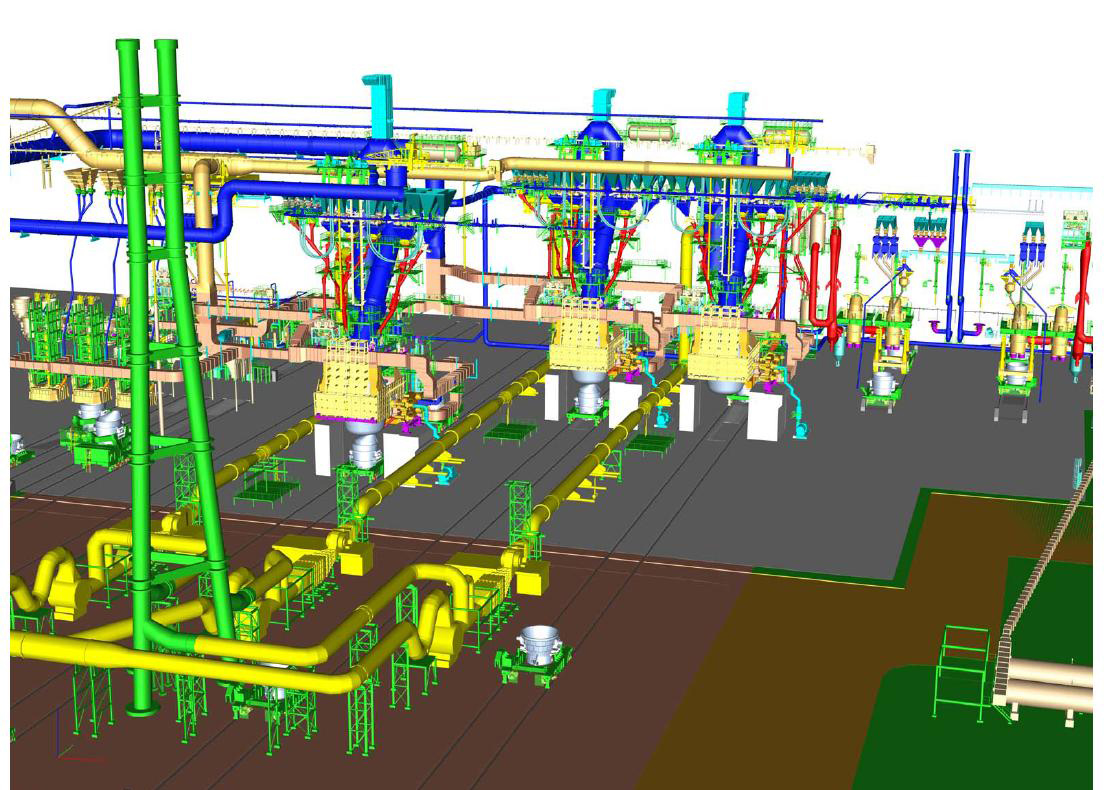

By making use of the know-how we gained through our rich experience constructing steel manufacturing plants, we will provide optimal layouts. Along with our optimized handling methods for materials and molten steel ladles, we have introduced state-of-the-art technologies into the steel making processes. Thus, we can improve your productivity and reduce your basic operation costs. The technologies backed with our rich experiences will work extremely well, not only in green fields, but also in brown fields accompanied by the remodeling or renewal of an existing plant.

Production Volume Increase

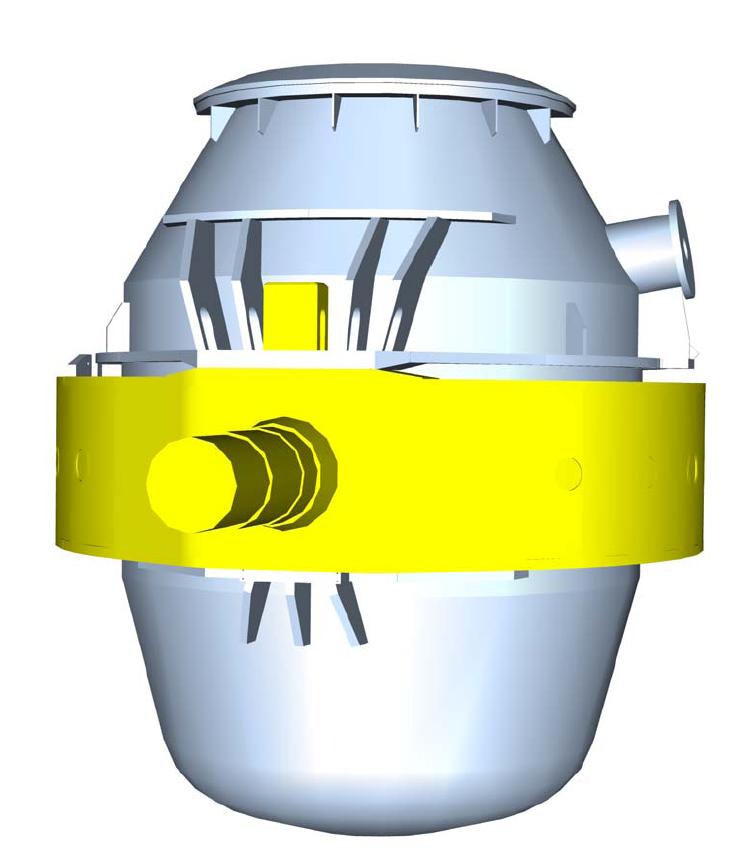

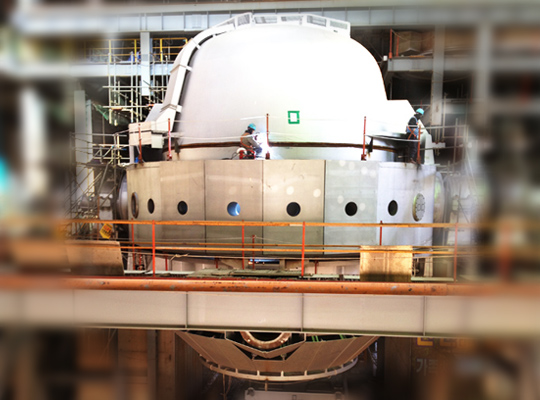

We have experience delivering converter systems with many different capacities, ranging from 60 to 330 t. A two-point support method is adopted for the furnace body, and necessary parts are cooled down. Moreover, the furnace bottom is replaceable, which can shorten the period required for furnace repair. Combined with auxiliary equipment, such as converter tilting devices, lance and sub lance facilities, secondary dust collecting facilities, alloy conveyance and charging facilities, ladle transfer cars, ladle maintenance stations, and converter brick laying devices, we will realize the most powerful steel making plant.

Customization

Experienced instructors, who have a good knowledge of production and maintenance in many places of the world, will strictly meet delivery times and secure product quality. Through effective installation work instructions and control of trial operations which are appropriate to each construction site, you can achieve a certain amount of production soon after the start of operation.