Solutions

Production Cost Reduction

-

100 kWh/t

Reduction of power consumption

-

1.5 %

Improvement of metal yield

-

1.0 kg/t

A unit consumption of electrode of about

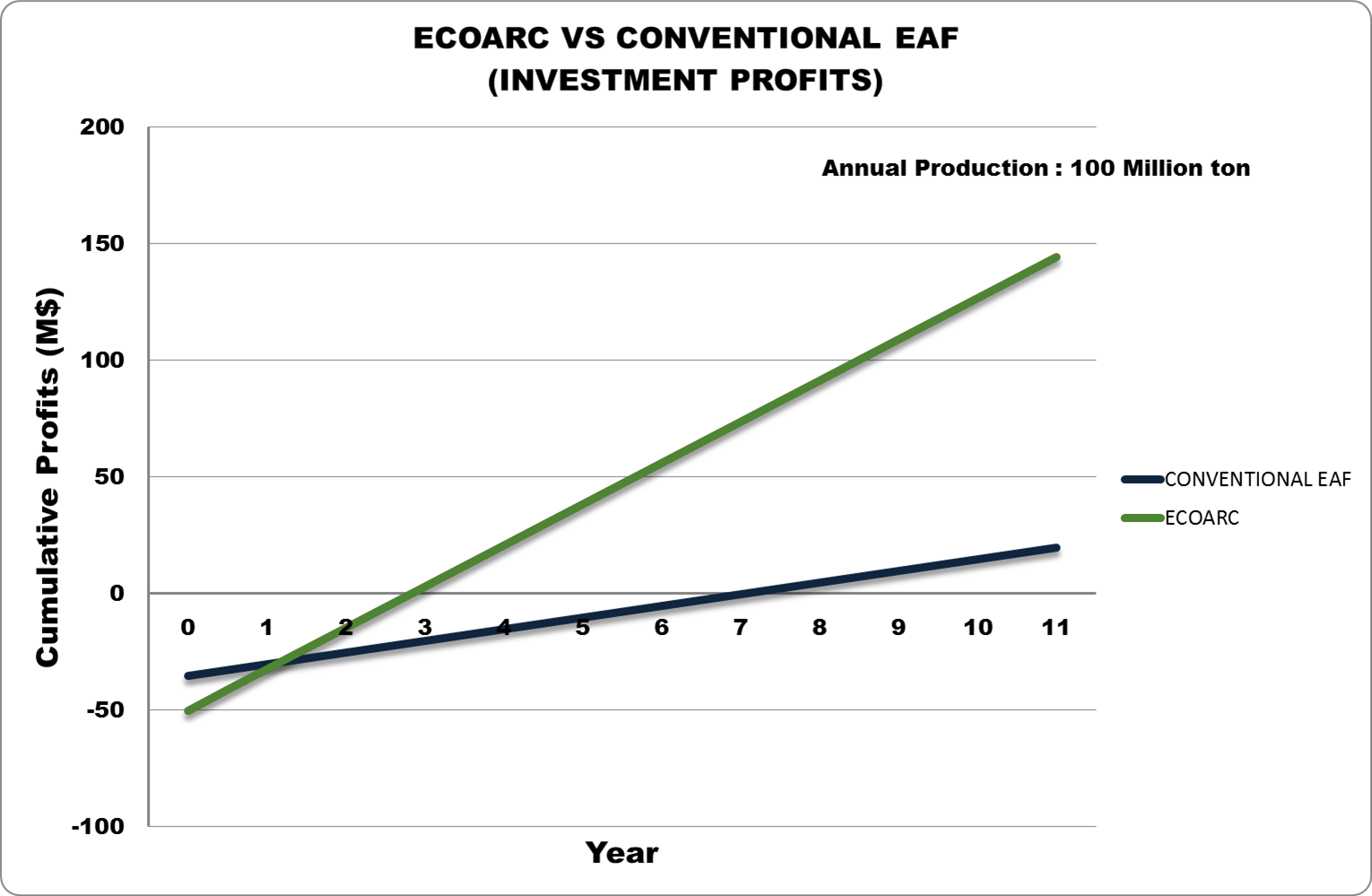

Installation of the ECOARC™ can be realized an early recovery of the investment costs, and an increase in revenues. Although, the installation of the preheating system would increase initial costs in the short term, however, it will provide high investment returns, and customers will be able to enjoy high investment returns by dramatic decrease of production costs, and increase in high revenue.

You would feel the benefits of this investment immediately after installation through the phenomenal performance exhibited by the ECOARC™.

- Customer commentsUMC Metals Ltd., Thailand (2012) Mr. Schroer, Plant Manager

- “We are producing reinforcing steel bars to be used in a high-rise building. ECOARC™ is a strong weapon to become one of the most competitive producers in Thailand from the viewpoint of production cost. We hope to increase of greater domestic shares in a future.”

Environmental Friendliness

-

30 %

reduction of greenhouse gasses

-

0.1 ng-TEQ/m3N

Dioxin emission of not more than

-

40 %

reduction of dust emissions

Installation of the ECOARC™ will dramatically reduce the environmental impact.

- 1Reduction of greenhouse gasses

- 2Dioxin emission of not more than 0.1ng-TEQ/㎥N

- 340% reduction of dust emissions

- 415dB reduction of noise under operation

- 540% reduction of flicker levels

- 6Elimination of white smoke and foul odor generated during scrap preheating

Customization

Existing facilities can be reused when install the ECOARC™ system, it will contribute significantly to the initial investment cost reduction.

- 1Can reuse the existing building

- 2Can reuse the existing power supply facilities

- 3Can reuse the existing foundation

- 4Can reuse the existing water treatment facilities

- 5Can reuse the other existing auxiliary equipment