Solutions

Quality Enhancement

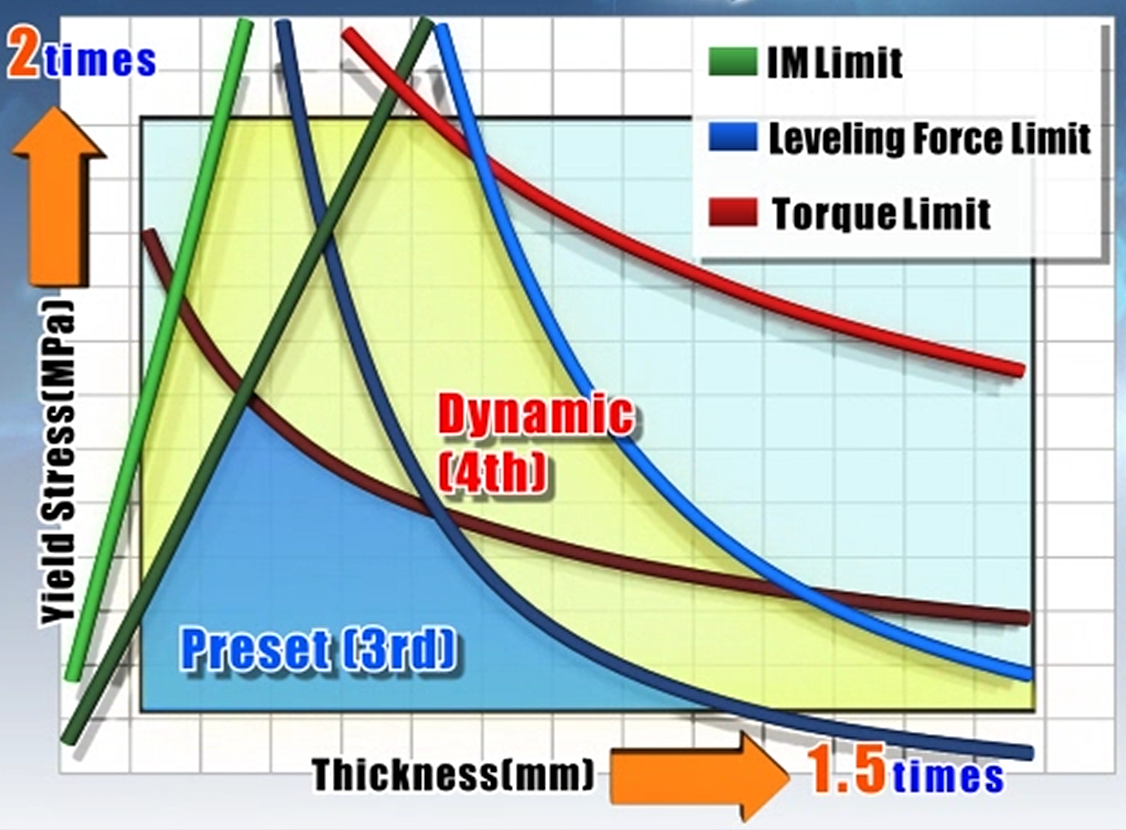

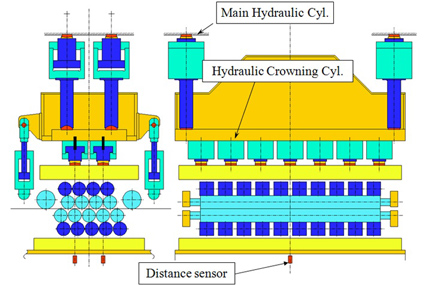

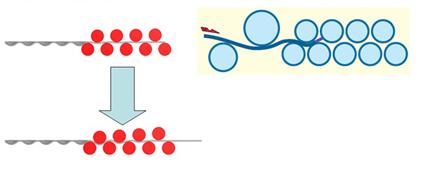

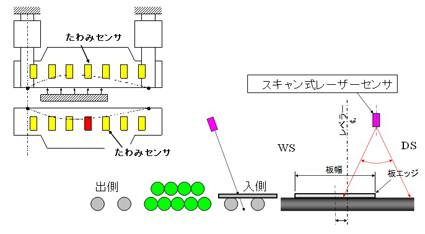

The SuPerLeveler™ utilizes the “dynamic crowning method” to control roll gap deviation throughout the entire steel plate, something that was not possible with conventional “preset levelers” (a method in which the amount of lateral deflection is set in accordance with the anticipated amount immediately before straightening begins). In particular, flatness is improved significantly within a range of approximately 1.2 m from the front and rear ends, compared to preset levelers.

Production Volume Increase

“High-load-capacity backup roll,” “bite correction control,” and other functions developed by JP Steel Plantech have significantly expanded the correctable range compared to conventional levelers.

Product Range Expansion

-

Increase by a maximum of 100 %

The plate yield stress range

-

Increase by a maximum of 50 %

The plate thickness range

Uniform correction of areas in which the front and rear edge straightening reaction fluctuates sharply as well as constant areas has been made possible, as has the reduction of residual stress in steel plates. This enables the manufacturing of steel plates that do not become deformed after cutting.